Perfect products from individually designed systems

Entire systems and lines

AN OVERVIEW

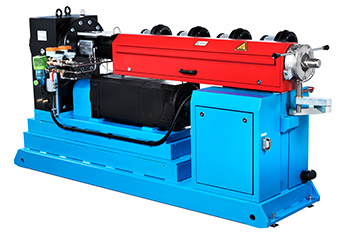

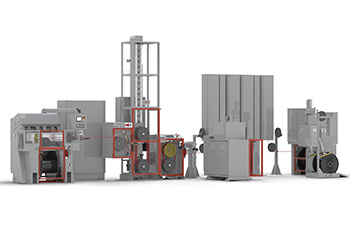

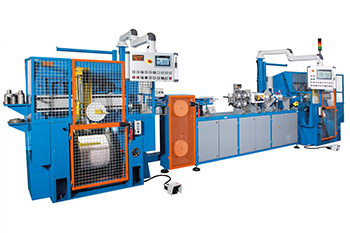

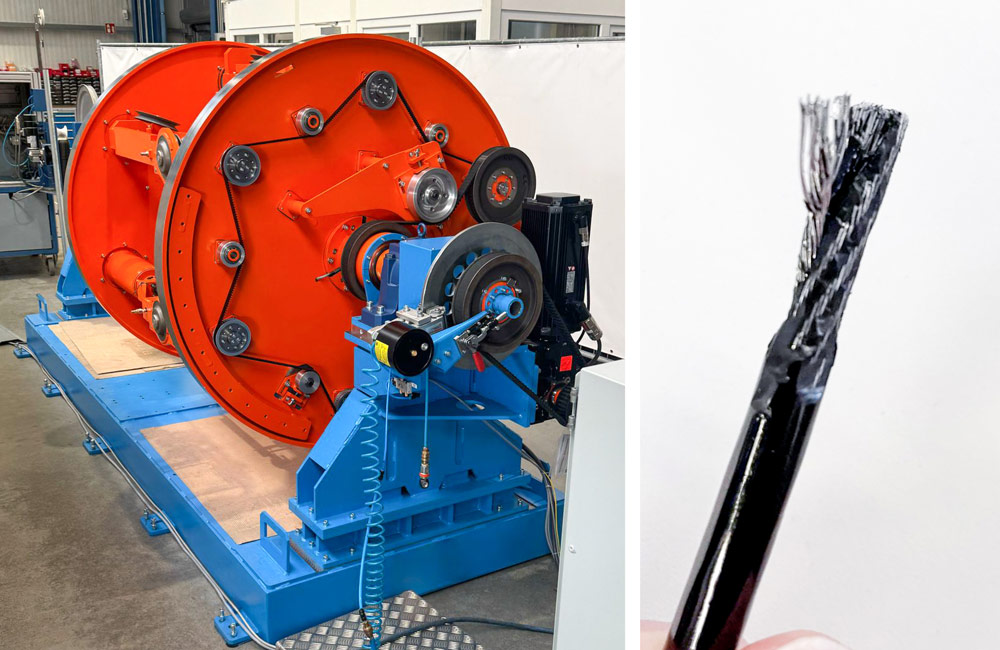

In the production of cables, pipes, and plastic profiles, further processing steps are carried out in addition to the purely manufacturing processes. This is essential because it enables our customers to upgrade their semi-finished goods into end-customer products.

Processes such as wrapping, testing, cutting, binding, foiling, packaging and palletizing are the main labor-intensive steps. The main focus of our solutions is for our customers to realize these processes in an automated and cost-effective way.

For the systems shown here: We also offer all products as variants that are customized to your specific requirements.

Industries and Products

VERSATILE AND UNIVERSAL

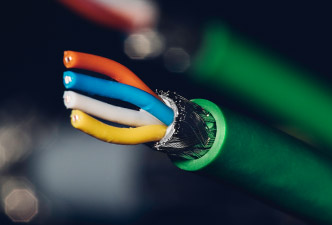

The areas of application for metallic communication cables are still very broad. Whether it is mini-coax, datacom or classic coaxial cables, their structure is usually very similar. A copper conductor (or copper-coated metals or alloys) with a predominantly 3-layer insulation body with inner layer, foam body and outer layer. After stranding and, if necessary, pair foiling, shielding and sheathing are applied in further production steps.

These cables are usually precisely specified in terms of their electrical and signal transmission properties. Forward and reverse attenuation play a special role and provide information about the quality of such cables.

KURRE Systems has the know-how in physical foaming, regardless of whether PE, PE or FEP/PFA is to be used.

KURRE System has developed its own key components for these product areas, including

- Gas dosing station (available for nitrogen or carbon dioxide)

- Mass pressure-controlled bypass for the foam extruder

- FFT/SLR measuring device for online measurement and detection of equidistant interference points on the cable

The demand for bandwidth in data transmission has risen sharply in recent years. This demand is driven by video conferencing, video streaming, TV over the Internet, video surveillance and much more. Fiber optic cables are laid both overland, outdoors (FTTx) and in buildings (indoor).

The requirements and designs of such cables are diverse. Due to different environmental conditions and population densities, fiber optic cable constructions are different in different countries and regions.

With machines and systems from KURRE Systems, a wide range of the above-mentioned fiber optic cables can be produced.

The diagnostic possibilities in medical technology for the benefit of our health have experienced a breathtaking increase in recent years. Many special cables are also used in complex and specific equipment.

Some of these are characterized, for example, by particularly small diameters and cross-sections – often smaller than AWG40. High-temperature-resistant cables are often used for the sheathing or insulation, and fluoropolymers are also used. Some of these are also physically foamed.

KURRE Systems has the appropriate machines and complete systems for both winding technology and extrusion, as well as the necessary know-how and decades of experience.

Cars have been undergoing continuous development for decades and there is still no end in sight. Many features are about to become standard, e.g. camera, radar, assistance systems, etc: Camera, radar, assistance systems etc. The demand for sensor technology and therefore also for cables in vehicles has risen sharply.

We are also currently experiencing a radical change in the automotive industry. It is well known that sales of electric and hybrid vehicles have risen sharply in many regions of the world. These developments have not only driven up volumes, but also the variety of types. In addition to classic vehicle cables, coaxial, bus and FO cables, as well as cables of higher temperature classes and busbars, are increasingly being used.

KURRE Systems has been supplying well-known players in the automotive sector for decades and is therefore the ideal partner for both “standard solutions” and specific “tailor-made” projects.

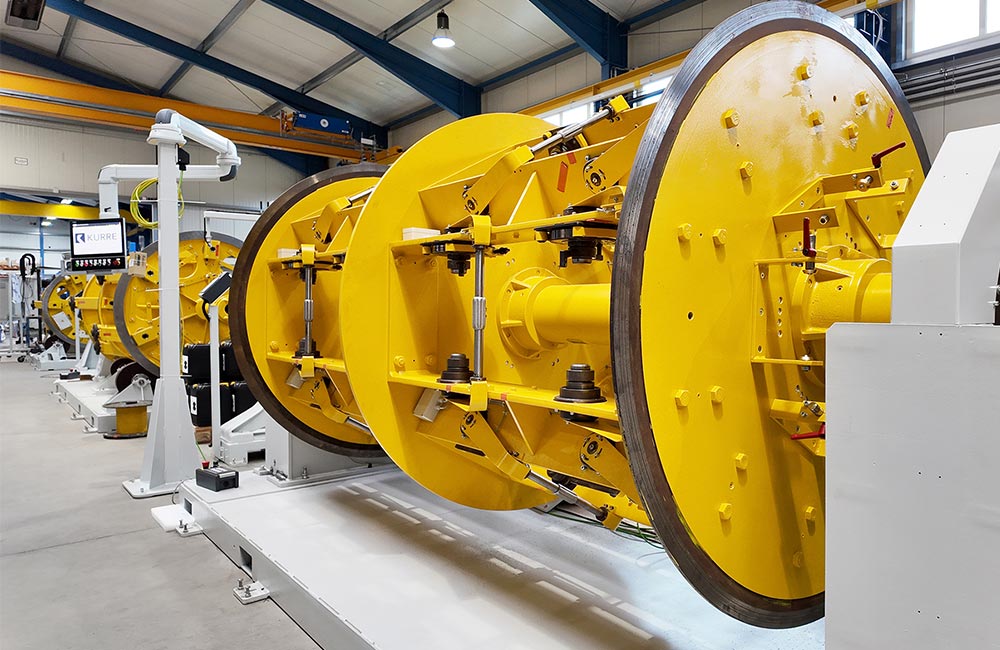

Global energy demand is rising continuously. Recently, more and more electrical energy has been generated from renewable energy sources ( solar power, wind power, etc.). Many cables are needed to distribute the energy generated. The product range in this segment is particularly broad.

KURRE Systems is one of the leading global suppliers and manufacturers of complete solutions and covers almost all cable types in the power cable sector up to 1 kV with its machines and systems. All plastics commonly used in this product segment are processed by KURRE Systems’ extruders to the highest quality.

KURRE Systems is a competent partner for building, industrial, control, device, PC and underground cables as well as special cables for mining and hybrid cables for e-mobility.

Also discover our individual components

MADE IN GERMANY