General product overview

General description of the product category

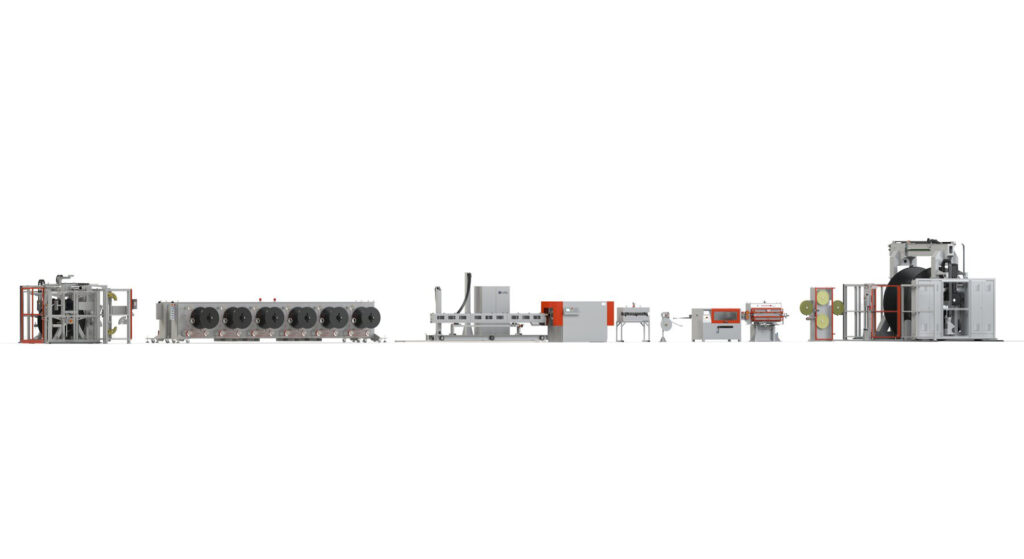

REWINDING SYSTEMS

Realizable designs

- Design as shaft, pintle or portal winder

- Fault detection with automatic fault positioning

- Inspection of diameter, knots, insulation, length and color

- Production of customer spools with calibratable length measurement

- Integration of customer-specific measuring devices

- Optional fully reversible design, i.e. can be used in both production directions without restrictions

Border areas of this product category

Spool flange diameter

100 – 3000 mm

Spool weight

max. 10,000 kg

Winding speed

max. 500 m/min.

Tension force range

1 – 2500 N