Foam extrusion isn’t just a specialty for us – it’s our everyday business.

As a hidden champion, we don’t just deliver machines – we deliver world-class, tailor-made process solutions designed specifically for the cable industry.

Why technicians and cable manufacturers trust us:

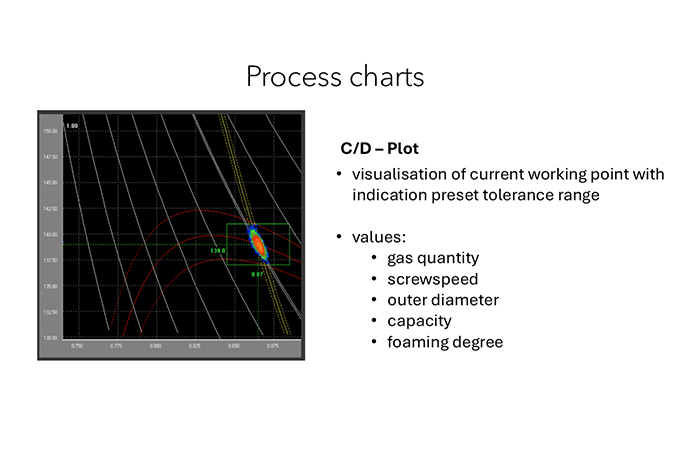

- Our proprietary control technology is one of a kind worldwide. It ensures maximum process stability – even with highly complex formulations, tight tolerances, and demanding materials.

- Next-level recipe management: Our in-house developed database doesn’t just store data – it links them with all relevant process parameters, analyses, and protocols – fully automated, traceable, and always accessible.

- These material data are also available in the customer’s dashboard, which can be accessed globally – transparent, secure, and in real time.

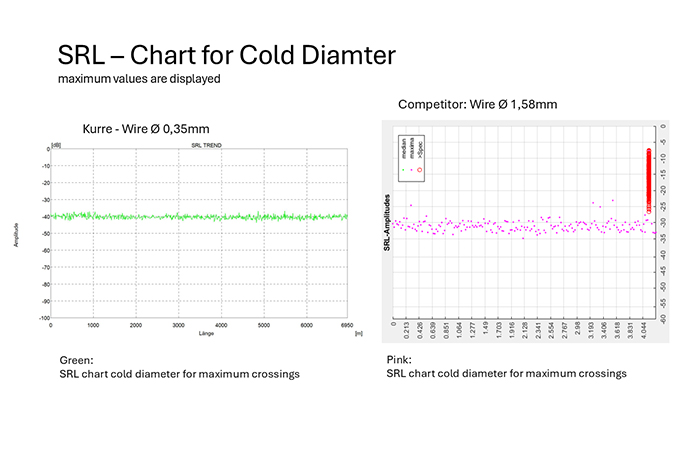

- Global accessibility: Whether it’s Plant 1 in Germany or Plant 3 in Mexico – all data is centrally available. Batch protocols, trend analyses, FFT or SRL evaluations – all at the push of a button.

- User-centric by design: Our systems are intuitive, low-maintenance, and seamlessly integrate into existing production environments.

- Everything from a single source: From extrusion lines to control systems and analysis tools – we deliver the complete solution. No patchwork, no interface issues.

Sustainability isn’t an afterthought – it’s built into our technology.

Our processes are designed to use materials efficiently, minimize waste, and optimize energy consumption – for a resource-conscious and future-ready production.

And the highlight:

We enable the production of the thinnest cables using fluoropolymers, designed for high-performance data transmission – with maximum precision, perfect cell structure, and absolute process reliability.

💬 For those who understand how demanding foam extrusion in cable manufacturing can be: we speak your language – technical, precise, and solution-oriented.

👉 Interested in a conversation at eye level? We’d love to connect.

Contact:

Thorsten Wilde

+49 4498 92 50 120