FIBER BUNDLING SYSTEM

KURRE Systems Develops Next-Generation Fibre Bundle Machine

The production of fiber optic cables comes with its own set of rules and challenges. Especially when manu-facturing long lengths with many individual fibers, the process is particularly demanding. To produce high-quality fiber optic cables efficiently and gently, KURRE Systems relies on pre-bundling the fibers using a state-of-the-art fibre bundle machine.

Specific Data

of the Fibre Bundle Machine

– Fibre bundling system with 3,000 revolutions/min

– Product diameter: 0,2 to 1.2 mm

– Tension forces: from 0.2 to 4 N

– Up to 14 winding stations

The German company KURRE Systems – a merger of KURRE Spezialmaschinenbau and SIEBE Engineering – has now taken a significant step forward in innovation: The newly developed fiber bundling system achieves an impressive 3,000 revolutions per minute while consistently delivering optimal results.

“KURRE has once again ventured successfully into new territory,” reports sales representative Joachim Lukassen. “We had the opportunity to design this fiber bundling system for a customer, and it was a direct hit. The focus during development was on fast yet extremely gentle processing of the individual glass fibers.”

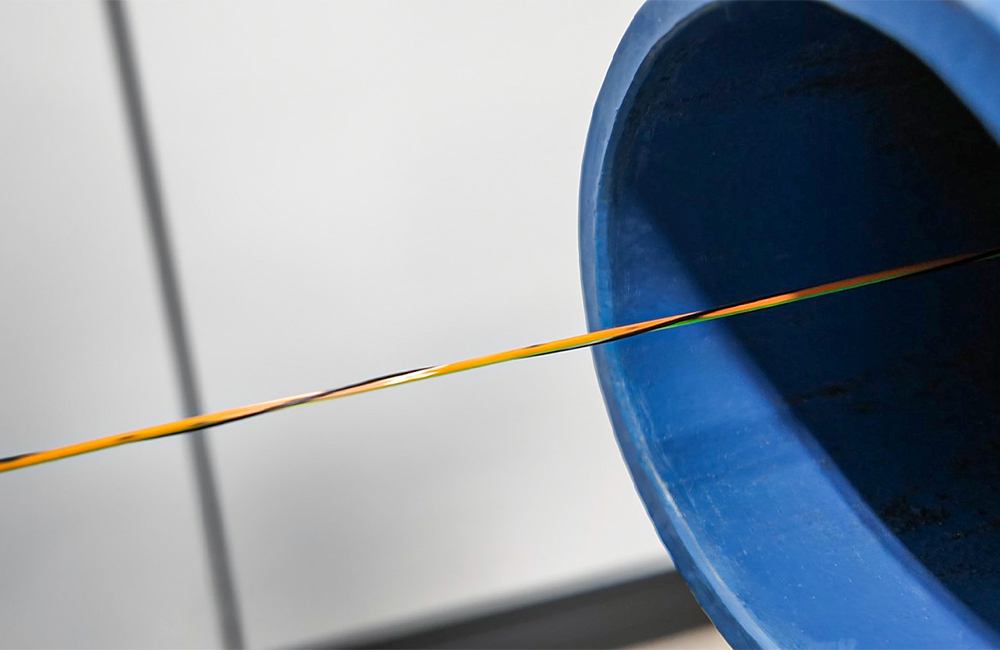

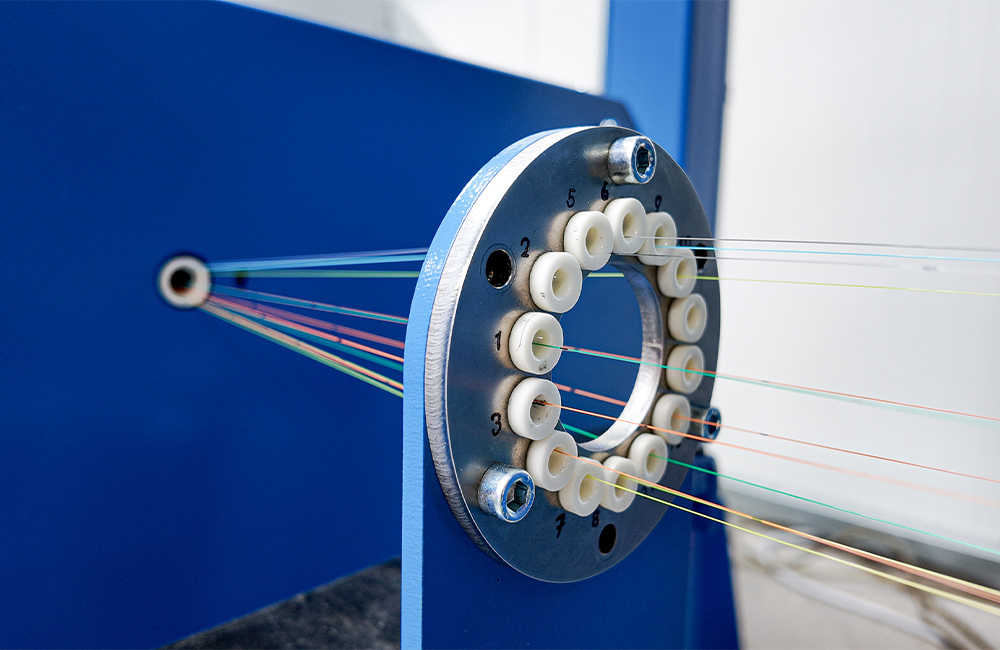

The new system handles ultra-fine glass fibers with diameters ranging from 0.2 to 1.2 millimeters within a sensitive tensile force range of only 0.2 to 4 Newtons. A multi-payoff unit feeds up to 14 individual fibers sim-ultaneously to the binder yarn spinner. There, the binder yarn – a wrapping thread – is gently and evenly wound around the fibers to minimize mechanical stress.

“The binder yarn, which wraps around all the fibers, also serves as a means of color-coding the bundles,” Jo-achim Lukassen explains. “This significantly simplifies identification and further processing.”

Thanks to a connected accumulator, enough spools can be held in reserve to process the full length of the input reels in a single run – almost entirely eliminating scrap lengths. A disc take-off provides the necessary drive, while a traversing winder gently coils the bundled fiber strands.

KURRE Systems is known for its custom-tailored machines and systems that meet individual customer re-quirements – and for its willingness to continuously explore new technological ground. For this fiber bun-dling system as well, all parameters – such as the number of winding stations or the tension ranges – were configured to match the customer’s specifications. This consistent commitment to customization has made KURRE a leading provider of special-purpose machinery for the wire and cable industry for decades.

“Currently, more binder yarn spinners are already in production – and the matching bundle lashing system for further processing of the fiber bundles is also being built,” Lukassen concludes.