General product overview

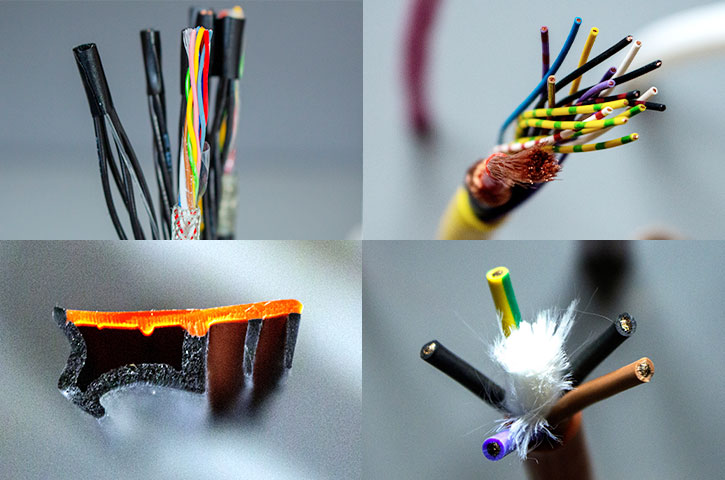

General description of the product category

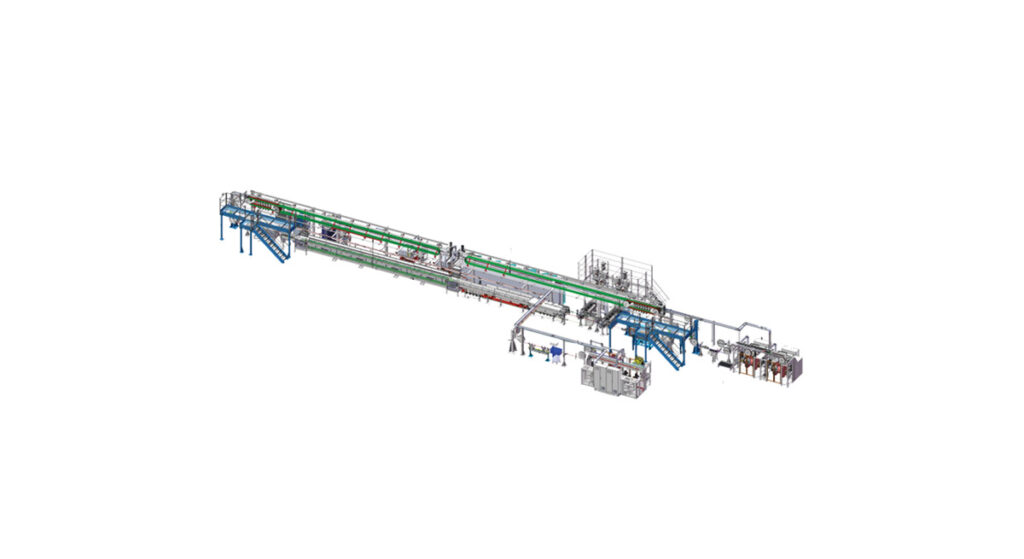

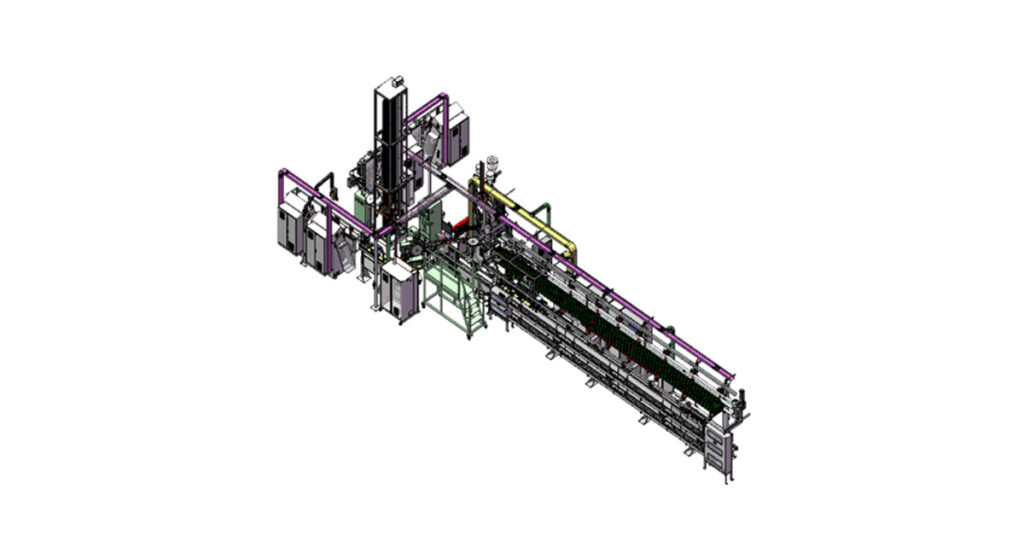

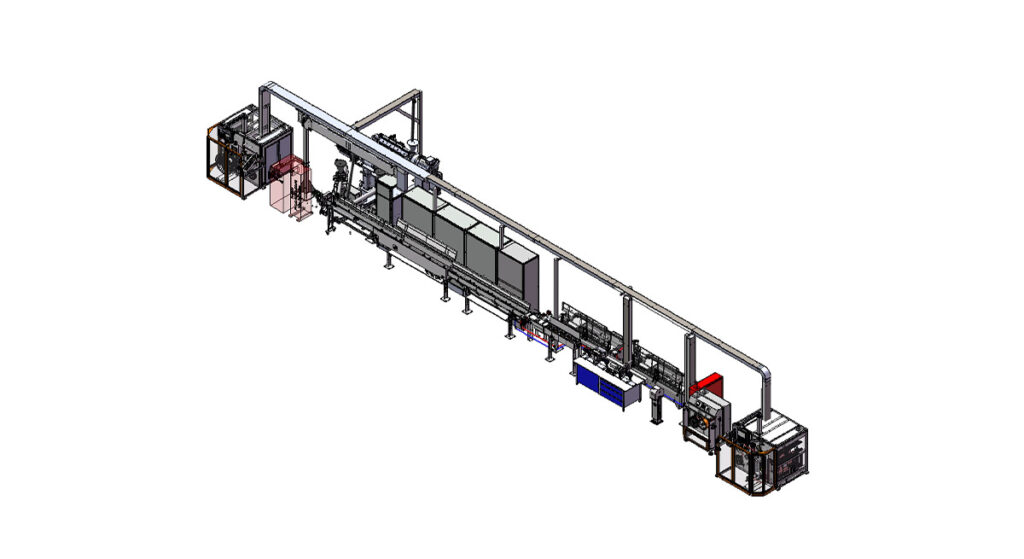

EXTRUSION LINES

Realizable designs

- High performance in all extruder sizes

- Computer calculated screw geometries, which are adapted to the respective polymer

- Material-conserving plasticizing

- Highest temperature and pressure stability

- Very good sliding properties

- Minimum wear

Our extrusion lines are primarily used for cable production. A physical process is used to apply molten material, for example plastic, to various wires and to coat them.

Furthermore, tubes, solid plastic rods, medical technology products or highly complex sheathed cables can be produced in this way.

- Automotive

- Data communication cable

- Fluorine / high temperature cables

- Coaxial cable

- Fiber Optic Cable

- Low voltage / buildings

- Profiles / Hoses

Border areas of this product category

Main extruder

diameter 18 – 150 mm

Co-extruder

diameter 18 – 65 mm

Laboratory extruder

diameter 18 – 150 mm