MACHINES +

The perfect solution for every project

Machine-types

AN OVERVIEW

The following applies to the machines shown here: We also offer all products as variants that are customized to your specific requirements.

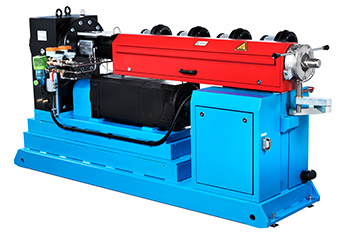

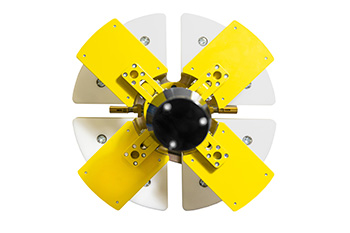

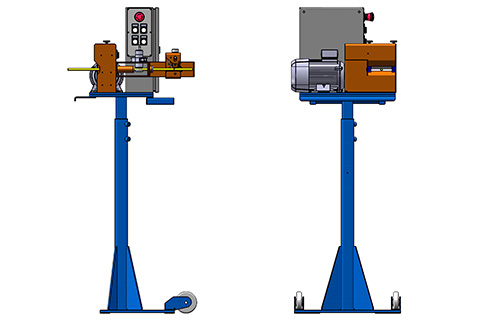

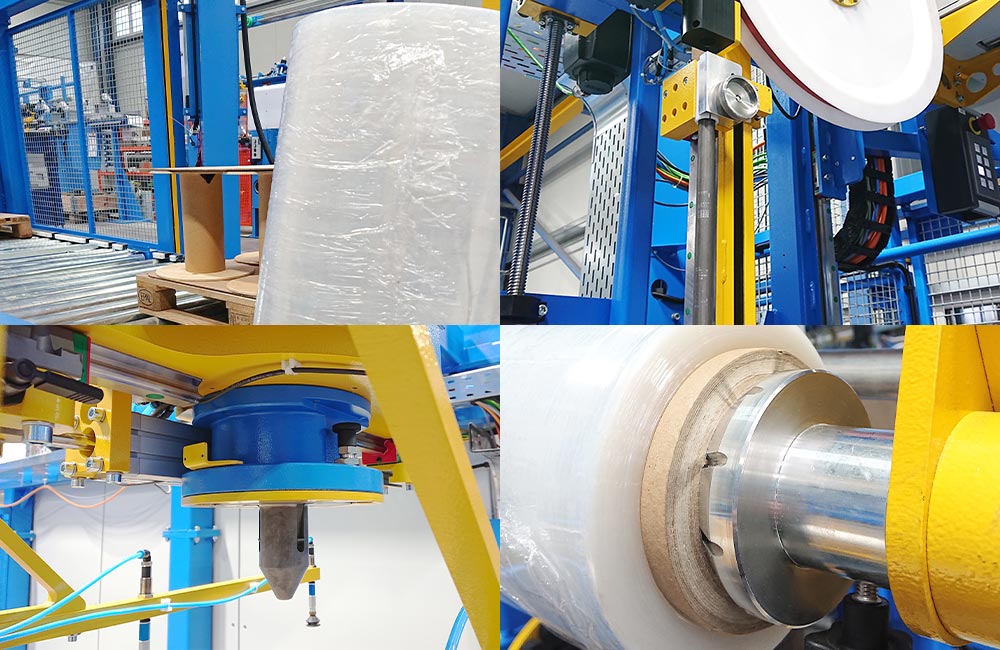

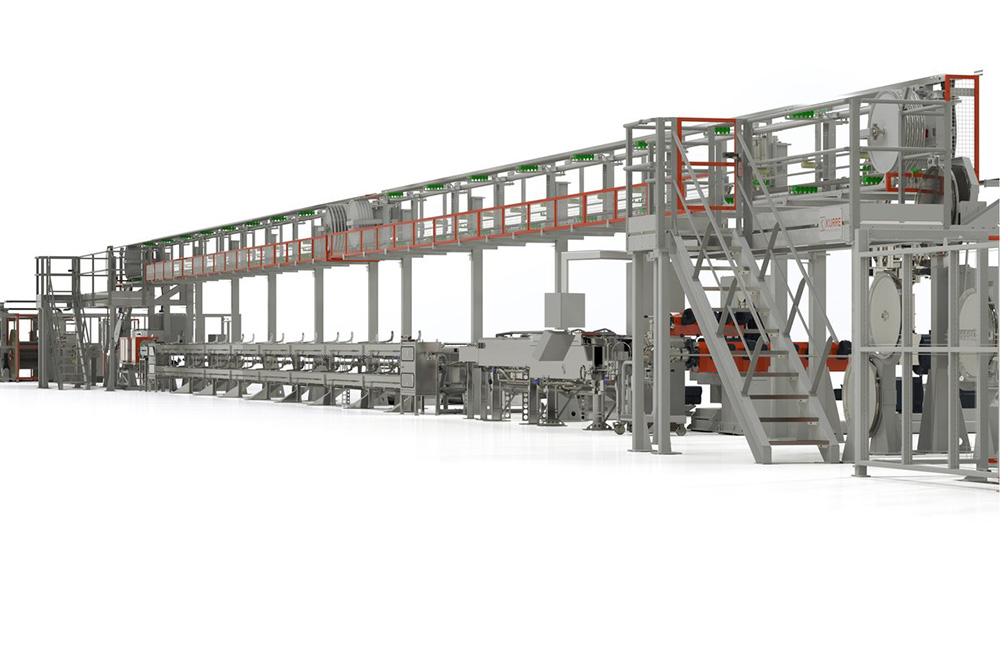

Pay-off, Take-up and everything in between

MACHINES AND INDIVIDUAL COMPONENTS

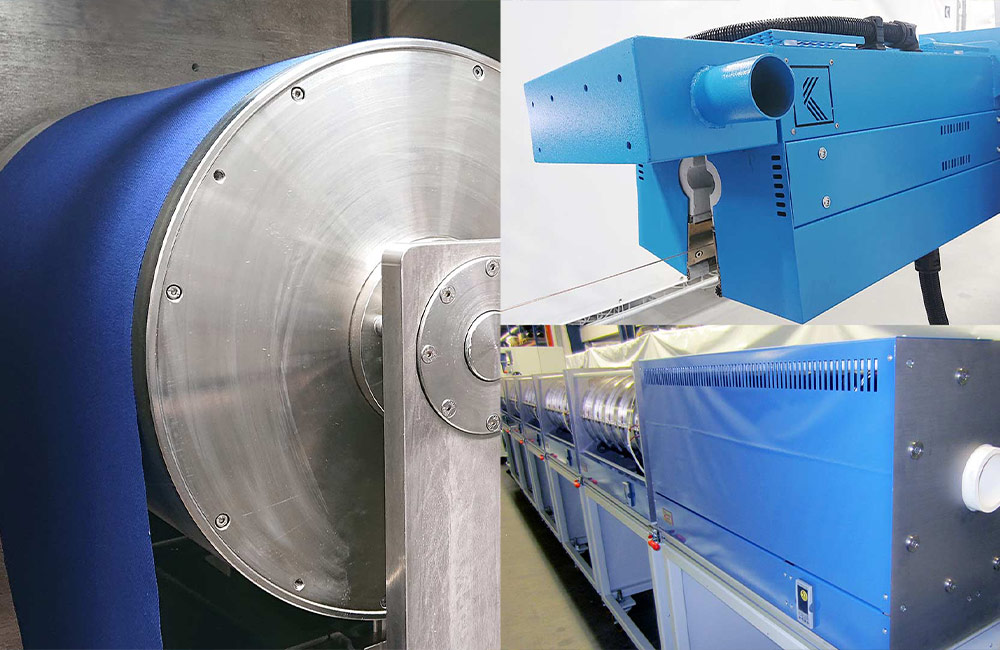

The production of high-quality cables, pipes and plastic profiles requires not only qualified materials, but first and foremost machines that guarantee efficiency, ease of maintenance, durability and, above all, process stability in production.

We are aware of all these parameters and optimise our machine components according to these requirements. We are happy to take on specific requirements and customize our products to your needs.

The maximum with every project

THOUGHT OF EVERYTHING

At KURRE System, we divide the topic of sustainability into three segments.

- Energy efficiency: The development of machines with high energy efficiency, which consume less energy and thus lower operating costs and reduce CO2 emissions, is a central component of our machine design.

- Durability and service life: Sustainable machines are designed to have a long service life and require as little maintenance and repair as possible. This reduces the need for spare parts and extends the service life of the machines.

- Reusability and recycling: Designing machines with the subsequent recyclability of materials in mind helps to reduce waste and resource consumption.

As a leading machine manufacturer in the cable industry, we consider ergonomics and user-friendliness to be key aspects of our product development. We recognise the importance of our machines not only being efficient and powerful, but also safe and easy for operators to use. Here are the key principles we work to in terms of ergonomics and ease of use:

User-centered approach: we employ a user-centered approach that ensures our machines are tailored to the needs and abilities of operators. By involving operators in the development process, we ensure that our machines are intuitive to use and allow operators to work efficiently.

Ergonomic design: Our machines are developed with a focus on ergonomic design to ensure they maximize operator comfort and reduce the risk of injury or fatigue. This includes the design of control panels, handles, controls and access areas to enable a natural and efficient way of working.

Clear and intuitive user interfaces: We emphasise clear and intuitive user interfaces that allow operators to easily understand and effectively control the machines. By using easy-to-understand symbols, color coding and text, we make it easier to interact with our machines and reduce the risk of operating errors.

Safety: Operator safety is our top priority. We integrate safety features and precautions into the design of our machines to ensure a safe working environment. This includes the implementation of emergency stop switches, guards and safety zones to minimize the risk of accidents.

Training and support: We provide comprehensive training and support for the operators of our machines to ensure that they are familiar with the functions and operating procedures. Through training and training materials, we help operators realize the full potential of our machines and operate them safely.

Through our commitment to ergonomics and user-friendliness, we strive to develop machines that not only increase productivity, but also improve working conditions and promote operator well-being.

Safety in mechanical engineering is of crucial importance in order to prevent accidents at work and protect the health of employees. This includes various measures that are implemented throughout the entire life cycle of a machine.

Firstly, safety starts in the design phase. Our well-trained engineers must design the machines so that they are safe and minimize potential risks. This includes the integration of protective devices such as safety panelling, emergency stop switches and safety sensors to reduce hazards for operators. Machines should also be ergonomically designed to avoid strain and injury from repetitive movements.

Strict quality controls must be carried out during manufacture and assembly to ensure that the machines comply with safety standards. Clear labeling of danger points and instructions for safe operation are also required here.

Employee training is another important aspect. All operators and maintenance staff must be trained on how to operate and maintain the machines safely and how to react in the event of an emergency. This training should be repeated and updated regularly.

In addition, regular maintenance and servicing of the machines requires special attention. A maintenance schedule should be established and followed to ensure that machines are operating properly and potential safety issues are recognized and rectified in a timely manner.

KURRE Systems creates machines that function efficiently over a long period of time without the need for frequent repairs or spare parts. This aspect is crucial for the profitability of investments in machinery and equipment and also contributes to sustainability by minimizing resource consumption and waste.

To ensure the longevity of machines, various factors must be taken into account:

High-quality materials and construction: We use high-quality materials and always pay attention to the careful construction of our machines. Robust parts and components that can withstand the demands of use are essential.

Regular maintenance and servicing: Regular maintenance and servicing are essential to maintain the functionality and performance of the machines. Preventive measures allow potential problems to be recognised and rectified at an early stage before they lead to major damage. Our experts will be happy to advise you.

Modularity and flexibility: Our machine concept has a modular design, which means that the machine can be adapted to different requirements throughout its entire life cycle. Replacing or upgrading components makes it possible to meet requirements without the need for a complete new purchase.

As a machine manufacturer, we focus on offering customized solutions that meet the specific requirements of our customers. Our expertise lies in developing and adapting products and processes to ensure optimal performance and efficiency in various application areas. Here are some key aspects of our customized mechanical engineering services:

Customized machine development: we work closely with our customers to understand their unique requirements and design and manufacture customized machines to meet those exact needs. From concept development to commissioning, we support our customers with customized solutions.

Customization of existing products: In addition to developing customized solutions, we can also adapt existing products to meet the specific needs of our customers. These customizations can include changes to design, performance or functionality to enable optimal integration into existing processes.

Automation and robotics: We offer customized automation solutions that aim to increase productivity, improve efficiency and reduce costs. We offer solutions to develop customized automation systems that meet our customers’ requirements.

Consultancy and engineering services: Our experts are on hand to provide our customers with comprehensive consulting and engineering services to help them develop and implement customized solutions. From concept development to feasibility studies and implementation, we offer customized services that are tailored to the individual requirements of our customers.

Through our customized mechanical engineering solutions, we help our customers to optimise their production processes, improve the quality of their products and gain a competitive edge in the market. Our flexibility and commitment to excellence enable us to meet the ever-changing needs of our customers and deliver innovative solutions that support their success.

We also supply complete systems – customized for your product

MADE IN GERMANY

Available at short notice

STORAGE-MACHINES

The following machines are available at short notice.

We look forward to your enquiry and will be happy to advise you.